And available in two-part polyurethane epoxy and methacrylate technologies Pliogrip structural adhesives can be an effective solution in a wide variety of applications. In engineering structural design yield strength is very important.

Absorbed Energy Time Curves Of Hybrid Composites Containing A Empty Download Scientific Diagram

The Impact Performance Of Woven Fabric Thermoplastic And Thermoset Composites Subjected To High Velocity Soft And Hard Impact Loading Springerlink

3

Manufacturers produce these wraps by mixing carbon fibers with binding polymers such as epoxy polyester vinyl ester or nylon to create a lightweight but incredibly strong composite material.

Impact energy absorbed epoxy composite. An epoxy containing carbon nanotubes is being used to make turbine blades that are longer stronger and lighter. Researchers estimate that curing a small section of the Boeing 787 carbon fiberepoxy fuselage requires 350 GJ of energy and produces 80 tons of carbon dioxide. The schematic of our wastewater treatment system is shown in Fig.

Nanotech is already helping increase the energy-efficiency of products. The potentially destructive energy of the incoming transient pulse is absorbed by the varistor thereby protecting vulnerable circuit components. The exceptional energy-absorbing ability of metal foams is characterized by the index σ ρl ε D which measures the energy absorbed in crushing the material up to its densification strain ε D σ ρl is the plateau stress.

Besides PGA also has superior mechanical strength to other biodegradable polymers 1617. Voltage is related to energy and work and energy also has this property that the total energy is not relevant because potential energy may be arbitrarily zeroed only the change in energy. Journal of Micromechanics and Microengineering JMM is a leading journal in its field covering all aspects of nano- and microelectromechanical systems devices and structures as well as nanomicromechanics nanomicroengineering and nanomicrofabrication.

Absorbed by the human body which is approved by US Food and Drug Administration UFDA. The energy absorption manifests itself in the form of dampening of vibrations and in the increase of fatigue resistance of a joint. Fibre-reinforced polymer FRP also Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibresThe fibres are usually glass carbon or aramid although other fibres such as paper or wood or asbestos have been sometimes used.

In vitro full-thickness mouse skin was more permeable to BADGE than was dermatomized rat or human skin with human skin showing only about 01 to 02 of applied dose absorbed within 24 hr with an. BCA operates out of its division headquarters in Renton Washington and has more than a dozen engineering manufacturing and assembly. Polymer-based adhesives have viscoelastic character and are thus capable of energy absorption.

The approximately constant value of the NFMR frequency f r e s in the range of the applied magnetic field H 05 kOe for the random 1 wt CNT30 wt BaFe 12 x Ga x O 19 epoxy composite and slightly increased f r e s for the aligned 1 wt CNT30 wt BaFe 12 x Ga x O 19 epoxy composite were explained by the lower saturation field H s a t compared to the pressed polycrystalline. Academiaedu is a platform for academics to share research papers. Impact test determines the amount of energy absorbed by a material during fracture.

In this research work we studied the microwave properties of multi-wall carbon nanotube MWCNT surface functionalized with metallic oxides composites. Impact resistance of woven composite laminates. Boeing Commercial Airplanes BCA is a division of The Boeing CompanyIt designs assembles markets and sells jet airliners and business jets Boeing Business Jets and also provides product-related maintenance and training to customers worldwide.

It is found that the mechanical strength and modulus are similar to that of human bones which make it an ideal candidate for hard tissue implanted materials. The surface-decorated CNTS were impregnated into polyurethane PU matrix. Metal foams absorb as much energy as tubes and do.

Other nanotech innovations may include a coating to reduce ice build-up. Autoclaving is the gold standard for composite curing however it comes at a high price and introduces part size limitations. 1 and includes five steps.

Three different concentrations 5 10 and 20 of metallic oxides were used namely cobalt iron and cobalt ferrite. Furthermore the use of composite cements is growing due to their lower carbon dioxide footprint. Consider Pliogrip adhesives for.

It is to determine whether the material is brittle or ductile in nature. Purpose of the test. In vivo BADGE was very slowly absorbed through the skin of mice.

Composite strength stiffness and thermal properties as well as failure modes can be affected by transverse matrix cracking. What Does Yield Strength Mean. Why impact test is done.

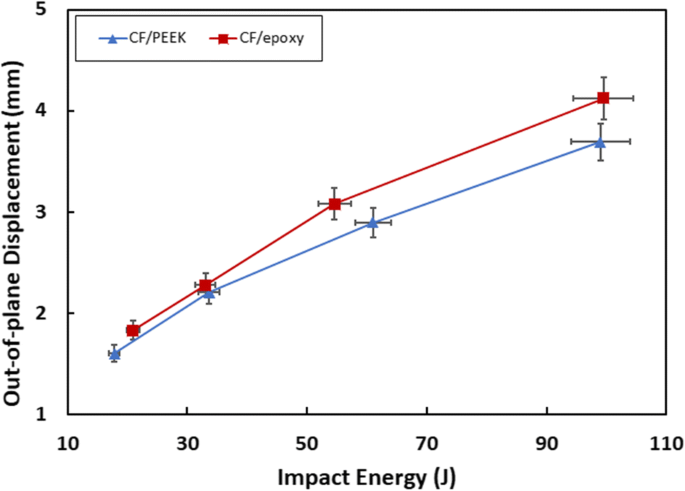

A the maximum force b the maximum displacement c the absorbed energy and d the damage degree. 1 H 2 O 2 electrolysers generate H 2 O 2 in a 01 M. Consider an electric charge q and it takes an amount of work W ab to move it from point a to point b.

Academiaedu is a platform for academics to share research papers. Since electrical conduction occurs in effect between Z N O grains distributed throughout the bulk of the device the Littelfuse Varistor is inherently more rugged than its single P-N junction counterparts such as Zener diodes. This absorbed energy is a measure of a given materials toughness and acts as a tool to study temperature-dependent brittle-ductile transition.

The peak force P max would increase with the increase of impact energy in the low-level range as shown in Fig. Yield strength refers to an indication of maximum stress that can be developed in a material without causing plastic deformationIt is the stress at which a material exhibits a specified permanent deformation and is a practical approximation of the elastic limit. The surface-decorated MWCNTs and the.

In retrofitting applications engineers simply wrap the material around concrete support columns of bridges or buildings and then pump pressurized epoxy into the gap between the column and the material. Figure 4-5 shows a reduction in stiffness as a function of crack density for a cross-plied carbonepoxy laminate. Atomically dispersed metal catalysts are of increasing importance in many catalytic processes but clear structural identification is challenging.

In general adhesives have a lower density than mechanical fasteners and so weight savings can be realized. 재료시험-기계적시험 Experimental Investigation on the Impact Resistance of Laminated Glass with Various Glass Make-ups 한글 재료시험-기계적시험 The certification of the absorbed energy 150 J nominal of Charpy V-notch reference test pieces for tests at 20 C-ERM-FA415ab 한글. We would like to show you a description here but the site wont allow us.

The Greatest Force Impact Energy Relationships When Carbon Epoxy And Download Scientific Diagram

Charpy Impact Test Of Epoxy Composites Reinforced With Untreated And Mercerized Mallow Fibers Sciencedirect

A Review Of The Crashworthiness Performance Of Energy Absorbing Composite Structure Within The Context Of Materials Manufacturing And Maintenance For Sustainability Sciencedirect

Izod Impact Energy As A Function Of The Fiber Fraction For The Neat Download Scientific Diagram

Charpy Impact Energy Absorption Of Some Composite And For Comparison Download Scientific Diagram

Charpy Impact Energy Absorption Of Some Composite And For Comparison Download Scientific Diagram

Kevlar

Energy Absorption In Composite Laminates Under Impact Loading Sciencedirect